Giriş

Follow this guide to remove and disassemble the traveling valve. You can then inspect or replace the valve, itself, or any of its components.

Neye ihtiyacın var

-

-

Remove the above grade riser pipe.

-

Firmly screw a T-handle onto the pump rod.

-

-

-

Use a pipe wrench to loosen and remove the pump spout.

-

Place the spout on a clean surface to prevent any contamination.

-

-

-

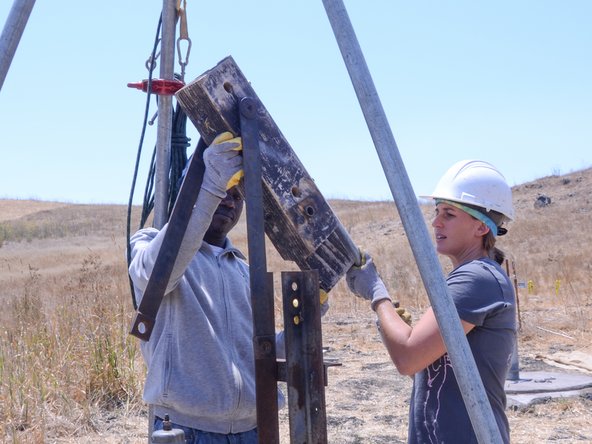

Place one wrench on the top of one of the pump riser plate bolts.

-

Place another wrench around the bottom of the bolt.

-

Pull the wrenches apart to loosen the bolt.

-

-

-

-

Insert a wrench into the slots located at the bottom of the traveling valve.

-

Using another wrench for leverage, unscrew the valve off the pump rod.

-

To reassemble your device, follow these instructions in reverse order.

To reassemble your device, follow these instructions in reverse order.